ENERGY EFFICIENCY

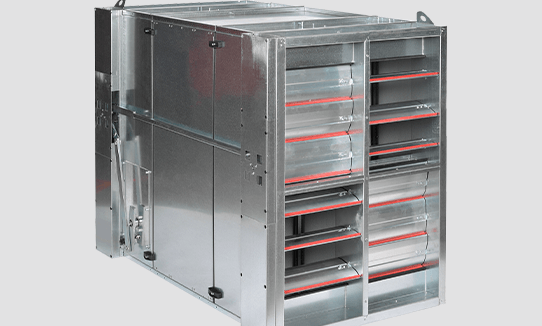

ENERGY RECOVERY

When conditioning large amounts of very cold, very warm or humid outdoor air, incorporating energy recovery into the design of an HVAC unit becomes especially important as a path to reducing energy costs. Air-to-air energy recovery provides economic benefits throughout the life of the HVAC unit.

Lower First Cost: Energy recovery devices reduce mechanical cooling and heating loads allowing the selection of a smaller capacity unit to provide the same levels of indoor ventilation and comfort.

Lower Operating Cost: Energy recovery devices reduce the amount of energy required to heat/cool/ventilate the building by tempering the outdoor air stream with the warmer/cooler exhaust air stream.

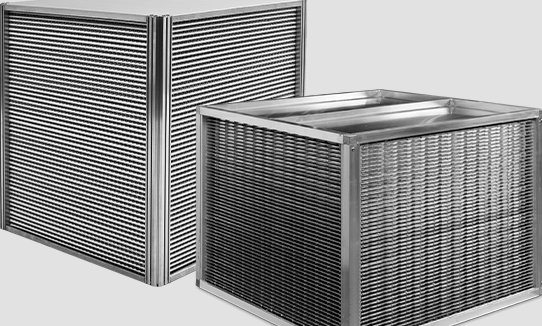

Plates

Fixed plate heat exchangers provide efficient energy recovery with low maintenance requirements due to no moving parts.

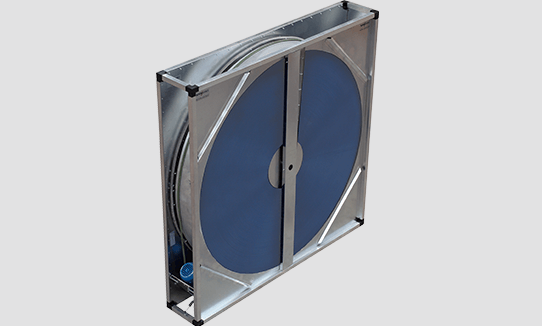

Wheels

Energy recovery wheels are the most efficient energy recovery option meeting all ASHRAE 90.1 requirements.

Additional Technologies

Choose from heat pipes, run-around coils or regenerative heat exchangers for additional energy recovery options.

ROBUST CABINET DESIGN

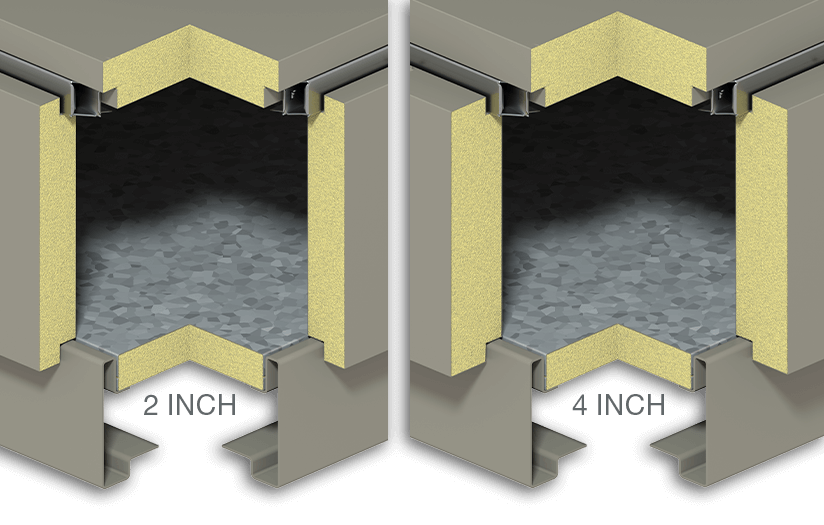

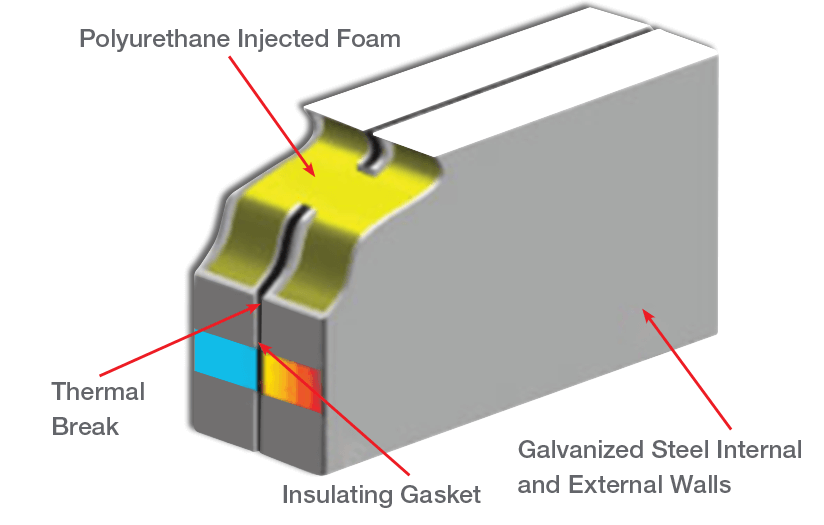

Confidently containing treated air within an HVAC unit is one certain path to energy efficiency. Eliminating, or at least minimizing, heat loss, unwanted outdoor air infiltration or conditioned air exfiltration, requires a robust unit casing. Cabinet designs using foam injected insulation with a thermal break design will create thermal integrity and increased casing strength.

R values of 6.3 – 7.1 per inch of foam insulation. 2” panels are up to R14. 4” panels up to R28.

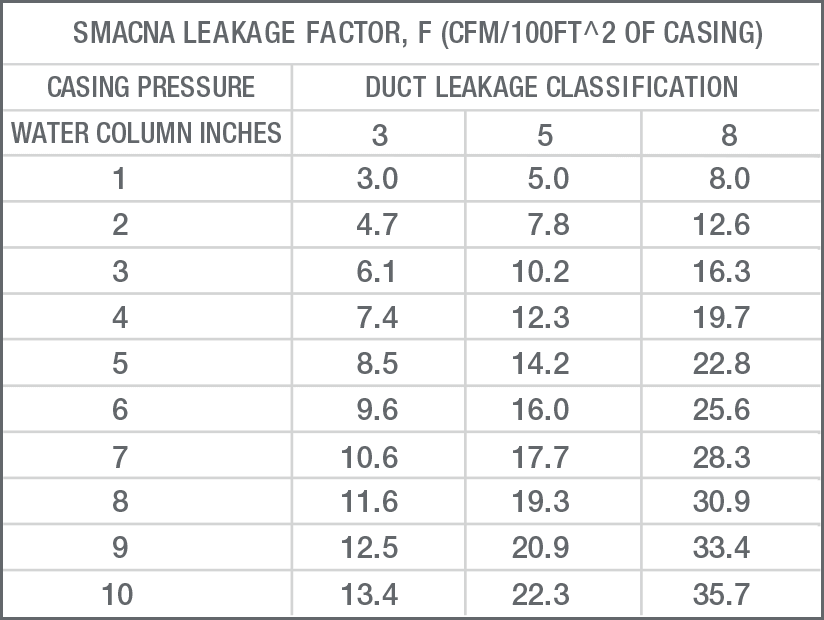

Low air leakage cabinet designs are also integral to energy efficiency. Use the SMACNA approved air leakage rating system to determine what level of performance makes sense for your project. The most energy efficient systems carry a SMACNA Leakage Class Rating of 5 or better with lower class rating numbers correlating to lower casing air leakage per square foot.

EFFECTIVE CONTROL

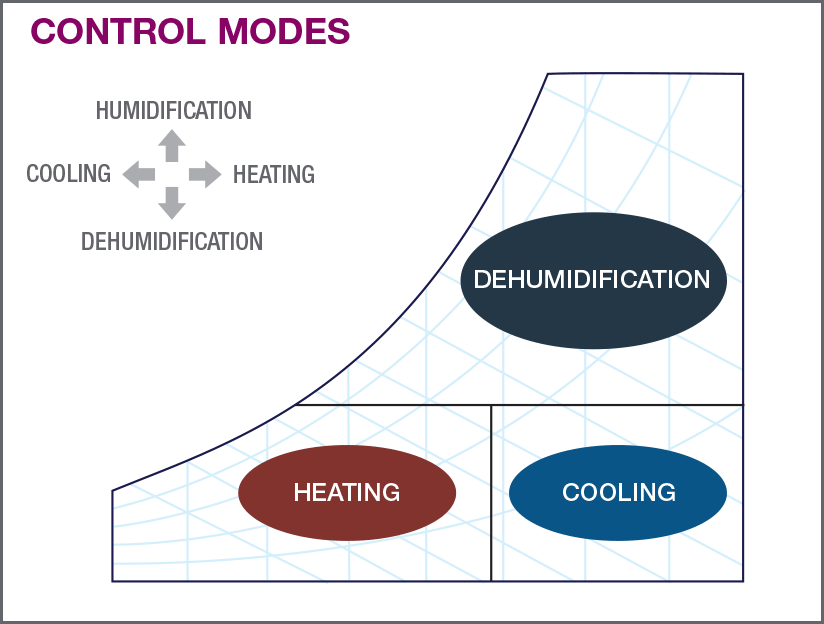

Operating efficiently is not just a mechanical issue. Proper control of mechanical components can make the difference between proper performance with low energy consumption and a unit operating out of specification.

Especially when introducing high amounts of outdoor air, having the proper control modes will dictate whether the space stays within desired operating parameters or drifts based on outdoor conditions. Dehumidification control is especially important to keep spaces in control. Many times, the approach to dehumidifying air is simply to cool it down to very low levels. Without the use of some sort of reheat, this simply creates a cold and clammy environment. Managing dehumidification by measuring dew point off the cooling coil and using hot gas reheat (from recycled energy) to warm the air to the desired discharge air temperature enables the delivery of tempered, dry air to the space.

A dedicated dehumidification controls mode activated based on outdoor air conditions versus space conditions allows proactive management of space conditions instead of the need to “catch up.”

Triggering Dehumidification Mode

Dehumidification Mode can be triggered by outdoor or indoor conditions.

- Choose Outdoor

Conditions if the unit is designed to provide:

- High percent of outdoor air

- High number of air changes

- Precise control of the space

Choose Space/Return Air Conditions if the unit is designed for:

High amounts of re-circulated air

High internal loads

WANT TO LEARN MORE?