HEATING DESIGN CHOICES FOR AIR SOURCE HEAT PUMPS

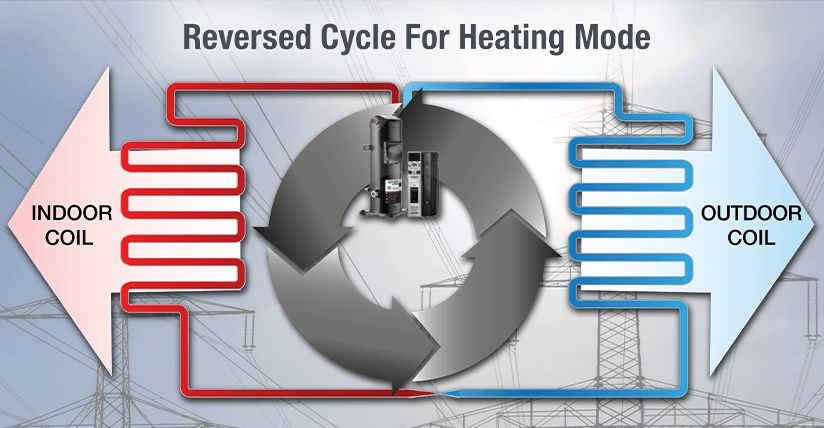

Air source heat pumps (ASHP) use a reversing valve that allows HVAC units to operate in both cooling and heating by reversing the refrigeration cycle, and capturing the heat of the compressor to warm the space the unit is serving.

Designing HVAC systems with ASHP has become a frequent choice of building designers and owners due to many factors.

- Energy efficiency

- Local codes

- Low carbon footprint

- Natural gas alternative

With all these benefits, the decision to design HVAC systems with ASHP functionality seems like the right choice for many buildings. However, the heating application of these units can be a challenge – and not just in sub-zero climates. To meet

and maintain a desired space temperature, the ASHP must deliver discharge air in a reliable and consistent manner. This may seem simple but the reality is that in heating mode many factors can get in the way. Extreme temperatures can cause the HVAC

unit to shut down. Cold, humid outdoor air will trigger a need to defrost the outdoor coil, which directs all or some of the compressor heat to the frosted coil and away from building occupants. Optimizing the unit design can help avoid these pitfalls.

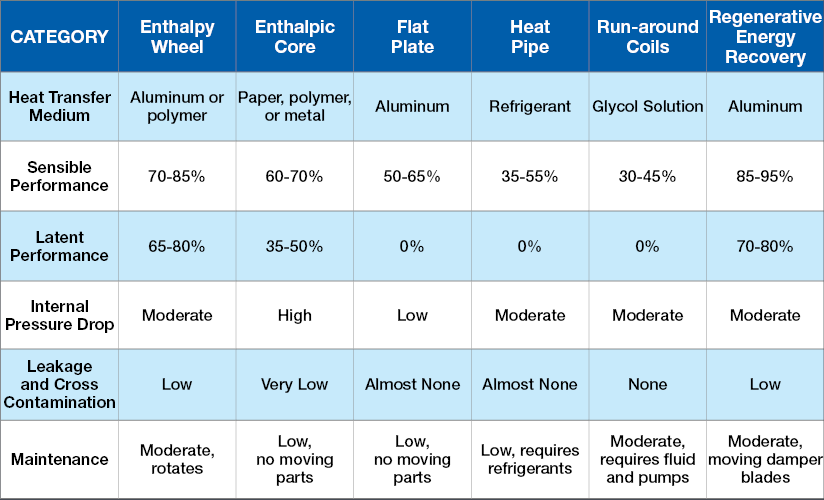

CHOOSE ENERGY RECOVERY

Pairing air source heat pumps with energy recovery extends the operating range of the unit, which is especially important when bringing in high amounts of outdoor air in colder climates. In order to ensure the compressor is able to start and operate within the operating envelope, the air approaching the coil must be at, or above, 30 °F. An energy recovery device can mix warm exhaust air with cool/cold incoming outdoor air to temper the air as it approaches the indoor coil, extending unit operation and reducing energy costs.

Many energy recovery technologies exist and choosing the right technology for the right application is generally a function of what the primary driver is for the building. If there is no on-site staff, a device with no moving parts like an enthalpic core may be best. If energy efficiency is most important, an enthalpy wheel may be the right solution. Regenerative heat exchangers have efficiences of up to 95% and can have a dramatic impact on the amount of heat needed to maintain space conditions. For ASHP applications, choose a technology that optimizes heating performance.

UNDERSTAND THE DEFROST CYCLE

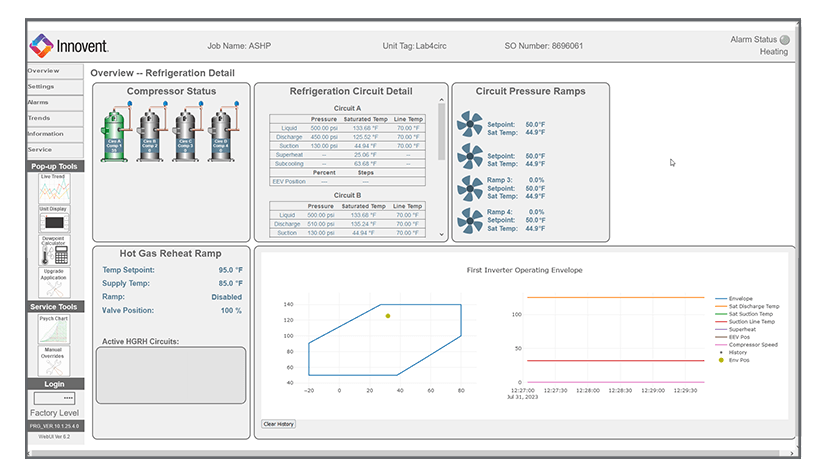

ASHPs have an inherent application challenge where frost can accumulate on the outdoor (evaporating) coil when the unit is in heating mode. Frost accumulation degrades the heating performance of the system and requires a defrost cycle to remove the frost and allow the coil to operate at maximum effectiveness. When the unit is in defrost mode, the heat of the compressor is re-directed away from distributing warm air to the space and instead toward the outdoor coil in order to melt the frost. This can result in little to no heat being directed to the space. The net result may be that the space begins to cool, many times below the desired setpoint. Two ways to address this challenge are either to reduce the frequency and duration of defrost cycles, or design a unit with multiple circuits allowing the unit to direct heat to both defrost and space comfort.

In order to reduce the risk that the unit goes into defrost unnecessarily, the defrost sequence should be initiated based on the right data. Some HVAC unit controllers are using outdoor air temperature as that trigger. However, the reality is that outdoor air dewpoint is actually more indicative of the possibility of forming frost. Cool (i.e. 40 °F), misty air on the outdoor coil of an ASHP unit can quickly create frost. Conversely, a cold (0 °F) day with little to no moisture in the air may not create frost conditions.

To design an ASHP with the most up-time in heating mode, designers should understand what triggers defrost, how long the defrost cycle lasts, and how the unit exits defrost mode. Look for measured inputs based on outdoor air dewpoint and saturated suction temperature as the optimal indicators that there truly is frost on the outdoor coil. Once saturated suction temperatures return to setpoint, or a maximum amount of time (in minutes) passes, the unit can stop defrosting and return to normal operation.

Another powerful option to avoid unit down-time during defrost is to choose a unit with multiple circuits. This allows the heat of one circuit to be directed to defrost while the remaining circuit(s) continue to provide heat to the space.

ADD SUPPLEMENTAL HEAT

While ASHP are an incredibly efficient way to heat a space, there are conditions where performance may be interrupted. These include:

- Ambient temperature below 0 °F

- Active defrost cycle to remove frost accumulation

The use of secondary heat in these instances – particularly SCR electric resistance heat – ensures consistent control over supply air temperatures. Other secondary heat sources for use when the ambient temperature drops below 0 °F include hot water coils, steam coils, indirect gas furnaces, and direct-fired gas furnaces.

Note that for both the compressor and the secondary heat source to run simultaneously, the electrical service to the unit must be sufficient.

WANT TO LEARN MORE?